Bending Machine HSE 2

Bending Machine HSE 3

Bending Machine HSE 5

Bending Machine HSE 5 with middle-foot-actuation

Bending Machine HSE 6

Bending Machine HSE 9

Roller Shear up to 0.80 mm

Roller Shear up to 1.00 mm

Manual Bending Machines

Model Standard HSE 2 – HSE 10

Standard Configuration

manual swivel bending machine in sturdy design

manual swivel bending machine in sturdy design - fast closing of upper beam by hand levers on both sides

- clamping system with eccentric tappet

- tooling of upper beam and bending beam are exchangeable

- adjustable stop for equal bending angles 0 - 155 degrees

- bending beam with pre-stressing mechanism (crown bow)

- weight compensation of upper and bending beam

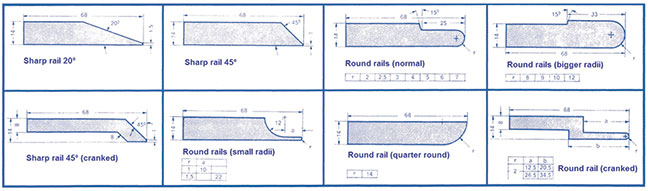

- upper beam with sharp rail 20 degrees

- bending beam with insert rail depending on type

- equipment with boreholes for the assembly of the back gauge/curl forming device

- retrofitting possibilty with curl forming device - roller shear extension

Optional accessory

- NEW back gauge adjustable from the front

- roller shear extension (1.00 mm)

- roller shear extension (0,80 mm)

- additional middle-foot-actuation for HSE 2 - HSE 9

- different tooling rail shapes for upper beam

- back gauge 600 mm (manual adjustment on both sides)

- back gauge 750 mm with gear rack adjustment

- insert rail for bending beam 50 x 10, 50 x 15, 50 x 20,

50 x 25 - curl forming attachment/2 wrenches/curl forming rod either 1000 or 2000 mm long

Profile rails for bending machines

Working length mm |

Bending capacity mm for steel 400 N/mm² |

Types |

|---|---|---|

| 1030 | 2.00 mm | HSE 2 |

| 1280 | 1.75 mm | HSE 3 |

| 1530 | 1.50 mm | HSE 4 |

| 2030 | 1.00 mm | HSE 5 |

| 2030 | 1.50 mm | HSE 6 |

| 2530 | 1.00 mm | HSE 8 |

| 3030 | 1.00 mm | HSE 9 |

| We reserve the right to change the illustrations and technical changes explicitly. For further informations and technical datasheets, please contact us. |